|

| Gold-coated mirror seen to nanometre scale |

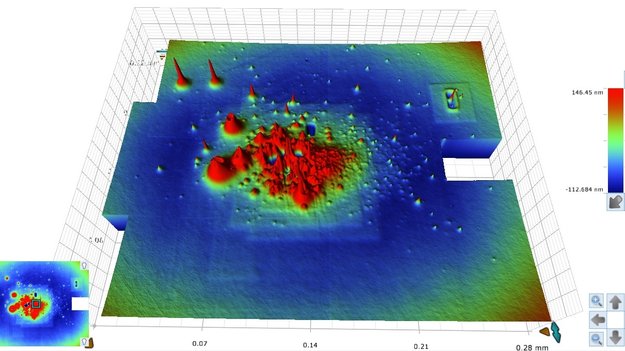

These images might resemble a planetary surface but actually show a different kind of alien environment: a microscopic view across a damaged laser lens, down to the nanometre level – a millionth of a millimetre, smaller than most individual bacteria.

ESA’s optics laboratory uses a powerful technique to zoom in on tiny areas, mapping each one in a few seconds.

With the microscope resting on a cushion of air to isolate it from external vibration, white light is split into two beams: one shines on the target while the other illuminates a near-perfect mirror. The reflected beams are then recombined. In a kind of high-tech ‘spot the difference’, the slightest differences between the two beams are recorded to build up the equivalent of contour lines on a map, revealing deviations from the shape of the reference mirror.

More typically used by the commercial semiconductor industry, its inbuilt software can process results immediately across its small field of view – less than a square mm – or multiple images can be swiftly stitched together into a panorama.

The optics laboratory, one of a suite of technical laboratories at the Agency’s ESTEC technical centre in Noordwijk, the Netherlands, uses this ‘white-light interferometric microscope’ to survey delicate optics for the slightest signs of damage after long series of laser bursts.

Lasers are versatile tools for space, useful for a variety of instruments such as radar-like ‘lidars’, which can sense a planet’s atmosphere in 3D and accurately measure global wind speeds.

But continuous laser firings can melt and eventually crack optical components, or unwanted condensation from tiny amounts of residual gases can build up on optical surfaces. Both can seriously affect laser performance and life.

ESA is seeking to understand these effects and come up with ways to avoid or eliminate them, perhaps by reducing ‘outgassing’ emissions or assessing safe laser energy levels.

A laser firing in space must be completely reliable over its entire mission lifetime – typically many years – because it cannot be repaired or serviced after launch. This can only be guaranteed by extensive testing on the ground.

This specialised microscope is sometimes combined with techniques from other ESTEC labs, such as the Atomic Force Microscope – which draws a nanometre-sharp stylus over surfaces to pick out the pattern of individual atoms – and the X-ray Photoelectron Spectrometer – which can identify the composition and structure of surface materials just a few nanometres deep.

No comments:

Post a Comment